Rooftop Anchor Certifications

At Expert Summit Anchors, we specialize in certified fall protection services to ensure safety compliance and protect your team across the United States.

Expert Summit Anchors: Your Partner in Professional Anchor Certification

Anchor certification is a critical safety requirement for any building utilizing rope descent and suspension systems. According to OSHA 1910.27, building owners are required to have their anchorage systems certified every ten years to ensure they can safely support a load of 5,000 pounds in any direction. This certification process, conducted by a licensed engineer, involves mathematical calculations and load testing to verify that the system is structurally sound. Without proper certification, building owners cannot legally contract services that require suspended access, and employers cannot allow their workers to use these systems, potentially putting lives at risk.

Why Anchor Certification is Important

Anchor certification plays a vital role in ensuring the safety of workers who rely on suspension systems for tasks like window cleaning, facade maintenance, or building repairs. Failure to properly certify these anchorage points can lead to catastrophic accidents. For example, if an anchorage point is weakened by rust or improper installation, it could fail under the stress of supporting workers, resulting in serious injury or even death.

Moreover, building owners are legally responsible for the safety of their anchorage systems. Before any rope descent system can be used, the building owner must provide written confirmation that the anchorages have been tested and certified. This written record must be maintained and presented to employers before work begins. Without this documentation, both the building owner and employer are at risk of violating OSHA regulations, leading to legal consequences, costly fines, and increased liability in the event of an accident. Regular certification ensures that all safety protocols are met and that the system can withstand the necessary loads to keep workers safe.

Frequently Asked Questions

-

What is anchor certification?

Anchor certification is the process of testing and verifying that anchorage points used for rope descent and suspension systems are capable of supporting a load of 5,000 pounds in any direction. This certification is required by OSHA and must be conducted every ten years by a licensed engineer.

This certification is required by OSHA and must be conducted every ten years and "signed off on" by a licensed engineer.

-

Why do I need to certify the anchorage points in my building?

Certification ensures that the anchorage system is safe and reliable for workers using suspended access systems. Without certification, you are not legally allowed to contract services requiring suspended work, and it puts workers at risk of serious injury or death due to potential system failure.

-

What happens if I don’t get my anchorages certified?

Failure to certify your anchorage points can result in legal penalties, fines, and increased liability in the event of an accident. Additionally, no employer will be able to use your system until proper certification has been obtained.

-

How often do I need to have the anchorages certified?

According to OSHA regulations, anchorage points must be certified at least every ten years, though annual inspections are required to ensure the system is in good working order.

-

What does the certification process involve?

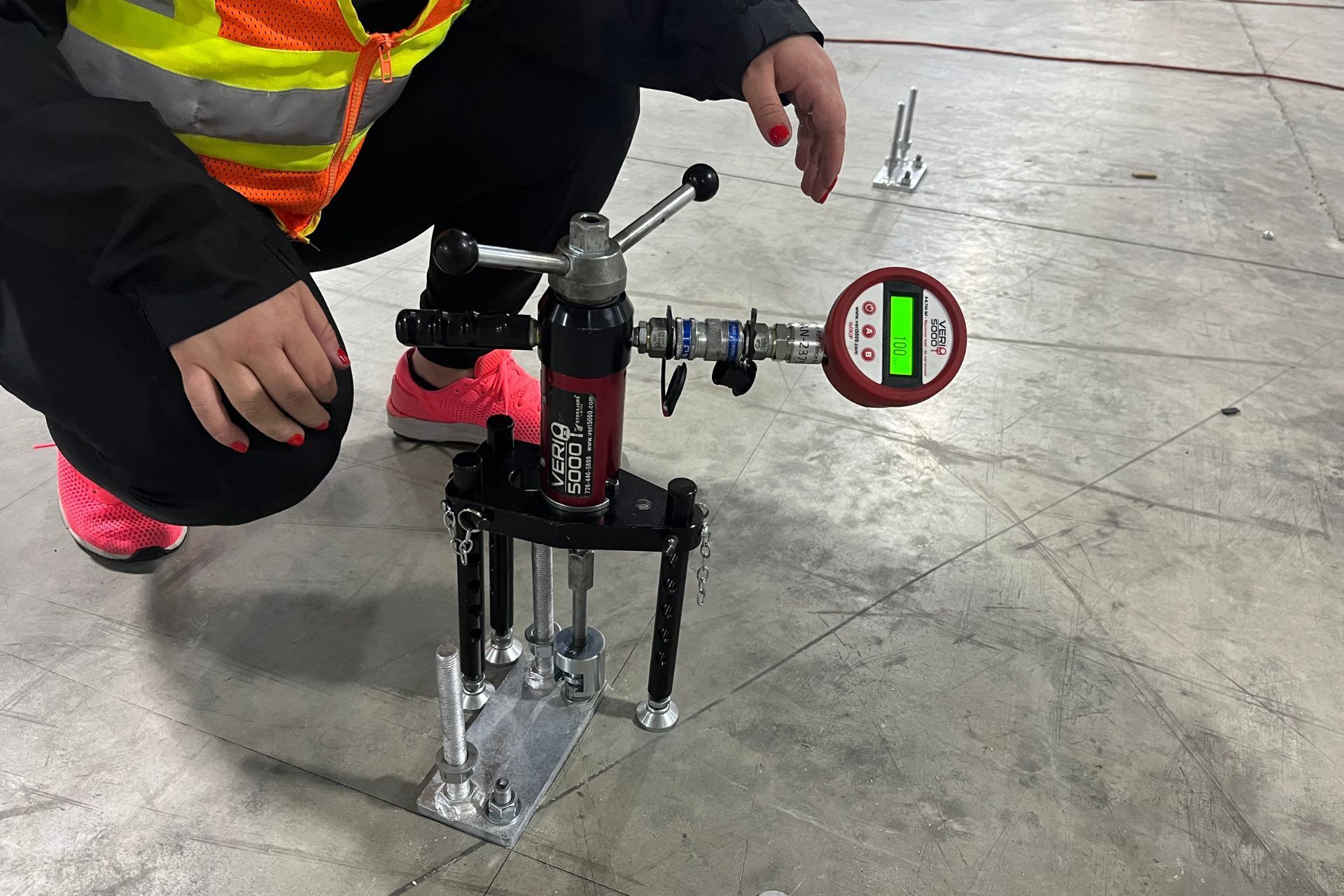

The certification process involves both mathematical calculations and on-site load testing to ensure that the anchorage can support 5,000 pounds in any direction. A licensed engineer will oversee the entire process and provide a detailed report outlining the results and the safety status of the anchorage system.

Anchor Certification

Under OSHA 1910.27 anchorage used for Rope Descent and Suspension are subject to a certification process on a 10 year increment. This process involves verifying that the anchorage and its connection are sound. In the testing the anchorage will be determined to support a load of 5000lbs in any direction. This process is done using mathematical calculations as well as in the field load testing and is done under the direction of a licensed engineer.

This certification must be done before a building owner is allowed to contract services that require suspended access utilizing the anchorage. In addition no employer is allowed to utilize employees in a suspended manner before this certification process takes place.

ESA will conduct all testing and provide a detailed report detailing background of anchorage and load testing results.

OSHA Regulations on Anchorages

1910.27(b)(1)

Anchorages.

1910.27(b)(1)(i)

Before any rope descent system is used, the building owner must inform the employer, in writing that the building owner has identified, tested, certified, and maintained each anchorage so it is capable of supporting at least 5,000 pounds (2,268 kg), in any direction, for each employee attached. The information must be based on an annual inspection by a qualified person and certification of each anchorage by a qualified person, as necessary, and at least every 10 years.

1910.27(b)(1)(ii)

The employer must ensure that no employee uses any anchorage before the employer has obtained written information from the building owner that each anchorage meets the requirements of paragraph (b)(1)(i) of this section. The employer must keep the information for the duration of the job.

1910.140(c)(12)

Anchorages used to attach to personal fall protection equipment must be independent of any anchorage used to suspend employees or platforms on which employees work. Anchorages used to attach to personal fall protection equipment on mobile work platforms on powered industrial trucks must be attached to an overhead member of the platform, at a point located above and near the center of the platform.

1910.140(c)(13)

Anchorages, except window cleaners' belt anchors covered by paragraph (e) of this section, must be:

1910.140(c)(13)(i)

Capable of supporting at least 5,000 pounds (22.2 kN) for each employee attached; or

1910.140(c)(13)(ii)

Designed, installed, and used, under the supervision of qualified person, as part of a complete personal fall protection system that maintains a safety factor of at least two.

Contact Expert Summit Anchors Today

Don't leave safety to chance. Ensure top-tier fall protection for your workforce—schedule your comprehensive assessment now. Take the first step toward a safer work environment and contact us today.

Expert Summit Anchors specializes in fall protection anchor inspections, certifications, load testing, and installation services across the United States of America. Trust Expert Summit Anchors for top-tier safety solutions and peace of mind.

Quick Links:

Services:

Contact Us:

Address:

Expert Summit Anchors

1701 E Empire St.

Ste 360-260

Bloomington IL 61704

Call Us:

E-Mail:

Cities we Service:

New York City, NY | Los Angeles, CA | Chicago, IL | Houston, TX | Phoenix, AZ | Philadelphia, PA | San Antonio, TX | San Diego, CA | Dallas, TX | San Jose, CA | Austin, TX | Jacksonville, FL | Fort Worth, TX | Columbus, OH | Charlotte, NC | Indianapolis, IN | San Francisco, CA | Seattle, WA | Denver, CO | Washington, D.C. | Boston, MA | El Paso, TX | Nashville, TN | Portland, OR | Las Vegas, NV | Detroit, MI | Memphis, TN | Louisville, KY | Baltimore, MD | Milwaukee, WI | Albuquerque, NM | Tucson, AZ | Fresno, CA | Sacramento, CA | Kansas City, MO | Mesa, AZ | Atlanta, GA | Omaha, NE | Colorado Springs, CO | Raleigh, NC | Long Beach, CA | Virginia Beach, VA | Miami, FL | Oakland, CA | Minneapolis, MN | Tulsa, OK | Bakersfield, CA | Aurora, CO | Arlington, VA | Wichita, KS | Orlando, FL | Jacksonville, FL | Miami, FL | Fort Lauderdale, FL | Gainesville, FL | Tampa, FL | Fort Myers, FL | Naples, FL

All Rights Reserved | Expert Summit Anchors